Sunlight Group successfully concluded the innovative R&D project SHB, for smarter and healthier lithium-ion batteries

The innovative R&D project of Sunlight Group and INEM, , implemented in the framework of the NSRF Operational Program “Eastern Macedonia and Thrace, 2014-2020,” has been successfully concluded.

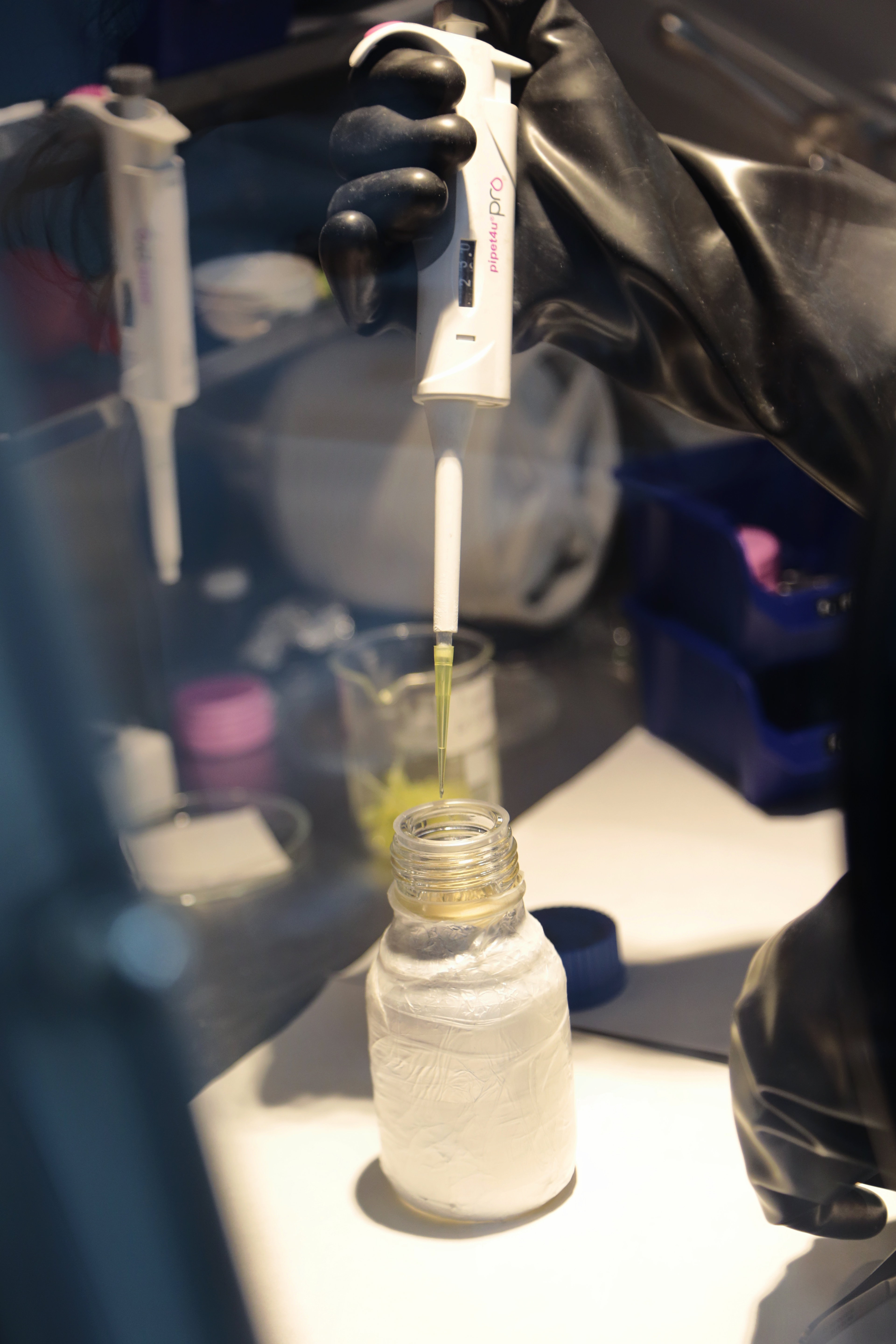

Under this collaborative Research, Development and Innovation project, Sunlight Group Energy Storage Systems, world-leading technology company and provider of innovative energy storage solutions, and INEM Technologies p.c., Xanthi-based academic spin-off company specializing in the development of innovative battery technologies, joined forces and capabilities to create “smarter” and “healthier” industrial lithium-ion batteries – i.e., better batteries. “Better,” because by rendering them “healthier” and “smarter,” their lifespan is also extended. And that means reduced environmental footprint, conservation of valuable and finite natural resources, and less waste.

The scope of this project, implemented from January 2021 until the middle of 2023, was to develop a robust prediction model for monitoring the State of Health (SoH) and State of Charge (SοC) of lithium-ion batteries for electric industrial vehicles – the type of batteries in the production of which Sunlight Group specializes. Also part of the scope is to integrate said prediction model into the Battery Management System (BMS) of Sunlight’s products, to optimize them.

The innovative approach of the SHB project was that it correlated the internal aging mechanisms and physical parameters (such as pressure and temperature) at the level of battery cell level, with the external electrical parameters of batteries to determine their State of Health (SoH) and State of Charge (SοC).

This correlation between internal and electrical parameters allows for the accurate estimation of SoC and enables users to optimize the potential of their energy resources, as they’re provided information about the remaining charge in their batteries. Reliable SoH determination, on the other hand, helps users assess the health of their batteries, allowing for proactive maintenance and replacement, as well as enhanced safety and performance.

The course of the research

The Smart Healthy Battery project evolved in three directions to analyze and utilize, in the best possible way, data sourced from the electrical and internal parameters of lithium-ion batteries for industrial applications. Namely, capacity loss; correlation of internal and electric parameters; and the development of a model for the accurate determination of SoC and SoH.

The specialized analysis of incremental capacity (IC) showed that the key mechanism leading to battery aging is lithium depletion, as well as the increase of internal resistance. In addition, the analysis demonstrated a strong correlation between pressure and stored charge, as well as pressure and SoH.

Following the above research results, a modified method was developed for the determination of SoC, taking into account the reversibly trapped capacity, caused due to variations in environment temperatures. Specifically, the method uses the volume of total charge loss when the discharge rate and discharge temperature differ from the battery specifications.

The benefits of the project

The implementation of the Smart Healthy Battery project led to significant observations and offers the opportunity for direct applications of its results. Specifically, the prediction model that was developed will be integrated into the BMS of Sunlight Group’s existing products, upgrading their specifications. This means that the initial scope of the SHB was fully achieved, as the R&D team contributed to further increasing the efficiency, reliability and safety of Sunlight’s energy storage solutions, thus rendering them even more competitive. The Smart Healthy Battery research project has multiple benefits:

FOR THE ENVIRONMENT: Maximizing battery lifespan, reducing environmental footprint, conserving natural resources, and avoiding hazardous waste.

FOR SUNLIGHT GROUP: Developing optimized, innovative, and even more competitive products that ensure increased productivity, thanks to the reduced downtime, as well as the smoother, more efficient, effective, reliable and safe operation of lithium-ion batteries for industrial mobility. And, consequently, holding an improved market position and offering better services to customers.

FOR INEM Technologies, p.c.: Implementing a research collaboration with a significant industry partner (Sunlight Group) and establishing a communication channel for leveraging synergies between academic R&D personnel and respective industrial departments.

FOR THE SCIENTIFIC COMMUNITY: Creating the conditions for scientists to grow and develop in the context of an attractive industrial-research environment, with a high level of specialization.

FOR THE REGION OF EASTERN MACEDONIA AND THRACE: Improving the battery value chain in the area. The implementation of the Smart Healthy Battery project may become a best practice example for other regional and other organizations to become a part of relevant value chains, via collaborations.